Nylon

About Nylon

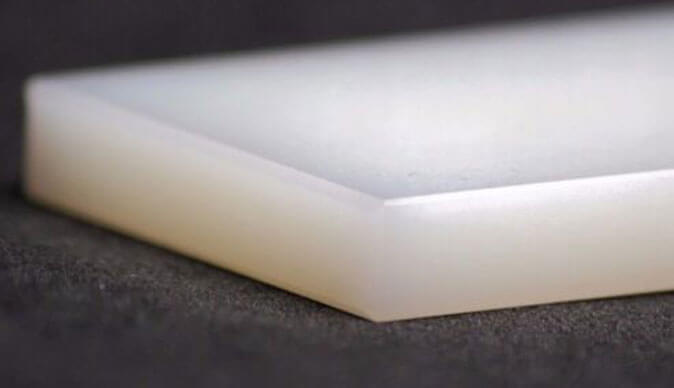

Nylon is a thermoplastic material that is known for its toughness, durability, and resistance to wear and tear. It is a synthetic polymer that can be moulded or extruded into various shapes and forms, making it a versatile material for a range of applications.

Nylon plastic is commonly used in the manufacture of products such as:

- Automotive parts: Nylon is used to make a wide range of automotive components, such as gears, bearings, bushings, and fuel tanks.

- Textiles: Nylon fibres are used to make a variety of textiles, including clothing, carpets, and upholstery.

- Electrical and electronic components: Nylon is an excellent insulator and is often used to make electrical and electronic components, such as connectors, switches, and circuit boards.

- Sports equipment: Nylon is used in the manufacture of a variety of sports equipment, including racquet strings, tennis balls, and fishing line.

- Consumer goods: Nylon is used to make a wide range of consumer goods, such as toothbrushes, luggage, and kitchen utensils.

Nylon is known for its excellent strength, toughness, and resistance to wear and tear, as well as its ability to withstand high temperatures and harsh environments. It is also lightweight, making it a popular choice for applications where weight is a concern.

Nylon plastic offers a range of chemical properties that make it suitable for various applications. Some of the key chemical properties of nylon include:

- Chemical resistance: Nylon is resistant to many chemicals, including acids, bases, and organic solvents. However, it can be attacked by strong acids or bases and some chlorinated solvents.

- Water absorption: Nylon has a relatively high water absorption rate, which can affect its mechanical properties. However, the degree of water absorption depends on the type of nylon and the environmental conditions.

- Temperature resistance: Nylon has good resistance to high temperatures, with some types of nylon being able to withstand temperatures up to 200°C.

- UV resistance: Nylon has moderate resistance to UV radiation and can be stabilized against UV degradation by adding suitable additives.

- Flammability: Nylon is a self-extinguishing material, which means it will stop burning once the flame source is removed.

- Barrier properties: Nylon has good gas barrier properties, making it suitable for use in packaging applications where oxygen or moisture ingress needs to be minimized.

It’s important to note that the chemical properties of nylon can vary depending on the specific type of nylon and the additives used in its manufacture. Therefore, it’s recommended to consult the manufacturer’s technical data sheet for specific information on the chemical properties of a particular type of nylon plastic.

Quick Enquiry

If you need help or a quote regarding any of our processes, materials or capabilities, please contact us on +44 (0)1903 235784 or complete the quick enquiry form below.

Nylon Enquiry

Why C&W Seals?

C&W Seals constantly review our activities to allow us to provide the latest products & manufacturing techniques in the marketplace. Our highly-trained staff specialise in the manufacturer of tailor-made products to meet specific customer specifications.

By regularly benchmarking our material prices we can guarantee new and current clients the best possible prices as well as bringing our clients the latest products with our forward thinking and dedicated mindset.

Need Help?

If you can't find the answer that you need, or would just like to speak to someone about any of our processes, mateials or capabilities, then please do get in touch.

Phone

Request a quote and we'll send it back within 24 hours

If you need a quote for Material Conversion, please complete our quote request form and we will send a quote back within 24 hours.