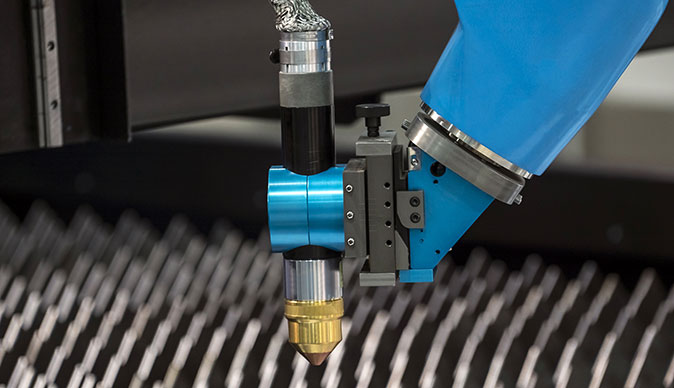

CO2 Laser Cutting

About CO2 Laser Cutting

CO2 lasers have found various applications in the gasket and seal industry, providing benefits such as precision, versatility, and speed. Here are the key benefits and uses of CO2 lasers in this industry:

Benefits:

- Precision Cutting: CO2 lasers offer exceptional precision, allowing for the accurate cutting of intricate shapes, patterns, and fine details. This precision ensures that gaskets and seals are cut to the exact specifications required for their intended applications.

- Clean and Burr-Free Cutting: CO2 lasers produce clean edges without the need for post-processing, such as deburring. This results in high-quality, ready-to-use gaskets and seals with smooth, polished edges.

- High Speed: CO2 lasers can cut materials quickly, making them suitable for high-volume production environments. This speed helps manufacturers meet tight deadlines and improve productivity.

- Customization: CO2 lasers are ideal for producing custom gaskets and seals tailored to specific designs, sizes, and material requirements. This flexibility allows manufacturers to address unique customer needs.

- Versatile Material Compatibility: CO2 lasers can cut a wide range of materials used in the gasket and seal industry, including rubber, foam, gasket materials, plastics, composites, and more. This versatility enables the use of the most suitable material for each application.

- Non-Contact Cutting: CO2 lasers do not make physical contact with the material being cut, minimizing wear and tear on the equipment and reducing the risk of material deformation or damage.

- Reduced Material Waste: The precision of CO2 lasers minimizes material waste by optimizing the layout of gaskets and seals on the material sheet, leading to cost savings and reduced environmental impact.

- Scalability: CO2 laser cutting systems can be scaled to accommodate different production volumes, making them suitable for both small-batch and large-scale manufacturing.

Uses:

- Gaskets: CO2 lasers are used to cut gaskets of various types, including flat gaskets, O-rings, and custom-shaped gaskets. These gaskets are essential for creating seals in machinery, equipment, and industrial processes.

- Seals: CO2 lasers are employed to cut seals for applications such as door seals, window seals, pipe seals, and automotive seals. These seals help prevent leaks, control noise, and maintain environmental conditions.

- Custom Gasket Production: CO2 lasers are particularly useful for producing custom gaskets with unique shapes, sizes, and sealing profiles. Manufacturers can quickly adapt to changing customer requirements.

- Prototyping: CO2 lasers are valuable for prototyping new gaskets and seals. Engineers and designers can rapidly iterate and test different designs before committing to full-scale production.

- Automotive and Transportation: The gasket and seal industry in the automotive and transportation sector benefits from CO2 lasers for precision cutting of gaskets used in engines, transmissions, exhaust systems, and other components.

- Industrial Machinery: CO2 lasers are used to create gaskets and seals for industrial machinery, including pumps, compressors, and hydraulic systems, ensuring efficient operation and preventing leaks.

- Construction: In the construction industry, CO2 lasers are used to produce seals for building materials and structures, including windows, doors, and roofing systems.

- Electronics: Gaskets and seals used in electronic enclosures are precisely cut with CO2 lasers to ensure proper sealing and protection of sensitive components.

- Medical Devices: CO2 lasers play a role in producing gaskets and seals for medical equipment and devices, ensuring hygiene and reliability in healthcare applications.

Some of the gasket materials that CO2 lasers can effectively cut include:

- Rubber: CO2 lasers can cut various types of rubber materials, including natural rubber, neoprene, EPDM (ethylene propylene diene monomer), silicone rubber, and nitrile rubber. Rubber gaskets are commonly used in automotive, industrial, and sealing applications.

- Foam: CO2 lasers are suitable for cutting foam materials, such as polyurethane foam, closed-cell foam, and open-cell foam. Foam gaskets are used for cushioning, insulation, and sealing purposes.

- Fiber Gasket Materials: CO2 lasers can cut fibre-based gasket materials like compressed non-asbestos fibre sheets, aramid fibre (e.g., Kevlar), and paper gasket materials. These materials are commonly used in automotive and industrial gaskets.

- Plastics: Various plastic gasket materials, such as PTFE (polytetrafluoroethylene), PVC (polyvinyl chloride), acrylic, and polycarbonate, can be cut with CO2 lasers. These materials find applications in electrical enclosures, plumbing, and more.

- Cork: CO2 lasers can cut cork gasket materials, which are used for their compressibility and sealing properties, often in automotive and industrial applications.

- Gasket Sheet Materials: Gasket sheet materials made of composite materials, graphite, and other compounds can be cut with CO2 lasers. These sheets are commonly used to create custom gaskets for specific applications.

- Thermoplastic Elastomers (TPE): TPE gasket materials, such as thermoplastic vulcanizates (TPVs), thermoplastic polyurethanes (TPUs), and thermoplastic olefins (TPOs), are compatible with CO2 lasers and used in various industries.

- PTFE Sheets: CO2 lasers are suitable for cutting PTFE sheets, which are often used for their excellent chemical resistance and low friction properties in sealing applications.

- Composite Materials: Some advanced gasket materials are made from composite materials that combine different layers or fabrics. CO2 lasers can be used to precisely cut these composite materials.

- Other Materials: Depending on the specific CO2 laser cutting system and its power, other gasket materials, including certain metals, ceramic fibre materials, and specialized high-temperature gasket materials, may also be cut with CO2 lasers.

Overall, CO2 lasers offer significant advantages in terms of precision, customization, and material versatility for gasket and seal manufacturing. Their ability to create high-quality, tailored solutions is valuable across a wide range of industries and applications.

Quick Enquiry

If you need help or a quote regarding any of our processes, materials or capabilities, please contact us on +44 (0)1903 235784 or complete the quick enquiry form below.

CO2 Laser Cutting Enquiry

Why C&W Seals?

C&W Seals constantly review our activities to allow us to provide the latest products & manufacturing techniques in the marketplace. Our highly-trained staff specialise in the manufacturer of tailor-made products to meet specific customer specifications.

By regularly benchmarking our material prices we can guarantee new and current clients the best possible prices as well as bringing our clients the latest products with our forward thinking and dedicated mindset.

Need Help?

If you can't find the answer that you need, or would just like to speak to someone about any of our processes, mateials or capabilities, then please do get in touch.

Phone

Request a quote and we'll send it back within 24 hours

If you need a quote for Material Conversion, please complete our quote request form and we will send a quote back within 24 hours.