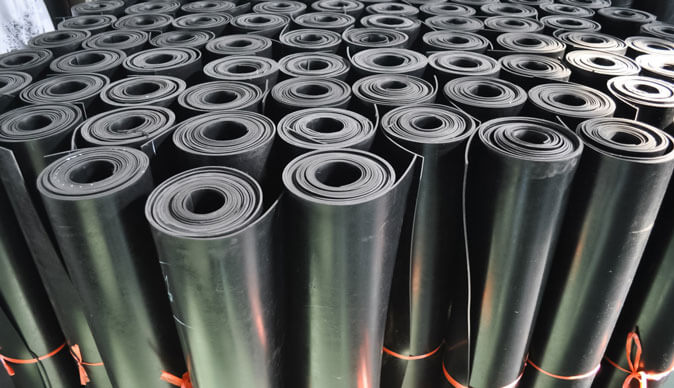

Rubber rolls are cylindrical or flat products made from rubber materials. They offer numerous properties that make them suitable for various applications.

Let’s delve into their key features and benefits:

- Excellent Elasticity and Resilience: Rubber rolls possess exceptional elasticity and resilience, allowing them to withstand repeated compression and retain their original shape. This property enables them to effectively absorb impact and provide cushioning.

- Superior Flexibility: Rubber rolls are highly flexible, adapting to different surfaces and conforming to irregularities. This makes them ideal for applications where a tight seal or contact is required.

- Impressive Abrasion Resistance: Rubber rolls exhibit excellent resistance to abrasion, ensuring their durability and longevity even in demanding environments. They can withstand constant wear and tear, making them suitable for high-friction applications.

- Good Chemical Resistance: Depending on the specific rubber compound used, rubber rolls can offer resistance to various chemicals, oils, solvents, and corrosive substances. This chemical resistance allows them to be used in environments where exposure to such substances is expected.

- Temperature Resistance: Rubber rolls can withstand a wide range of temperatures, from extremely low to high temperatures, without compromising their performance. This property makes them suitable for both cryogenic applications and high-temperature processes.

Common Uses of Rubber Rolls:

- Printing Industry: Rubber rolls are widely used in printing presses, where they serve as feed rollers, transfer rollers, and impression rollers. They provide a reliable grip, consistent pressure, and precise ink transfer for high-quality printing.

- Packaging and Converting: Rubber rolls are essential in packaging and converting equipment, such as laminators, slitters, embossers, and die-cutters. They ensure smooth material feeding, precise web tension control, and accurate cutting or embossing processes.

- Conveyor Systems: Rubber rolls are employed in conveyor systems to facilitate the movement of goods or materials. They offer grip, cushioning, and shock absorption, ensuring smooth transportation and minimizing product damage.

- Industrial Machinery: Rubber rolls find applications in various industrial machinery, including calendars, extruders, mixers, and presses. They provide traction, precise positioning, and vibration damping, enhancing the performance and safety of these machines.

- Automotive Industry: Rubber rolls are utilized in the automotive sector for applications such as vibration dampening, gasketing, sealing, and noise reduction. They can be found in engine mounts, seals, gaskets, suspension components, and weatherstripping.

Sponge Rolls:

Sponge rolls, also known as foam rolls, are made from open-cell foam materials with a soft and compressible structure. They offer unique properties that make them valuable in various industries. Let’s explore their key features and benefits:

- Excellent Cushioning and Shock Absorption: Sponge rolls possess outstanding cushioning properties, making them ideal for protecting delicate items during shipping or handling. They absorb impacts and vibrations, reducing the risk of damage.

- Lightweight and Flexible: Sponge rolls are lightweight and highly flexible, allowing for easy handling and conforming to different shapes. Their flexibility makes them suitable for wrapping irregular or fragile items securely.

- Sound and Thermal Insulation: The porous structure of sponge rolls provides excellent sound and thermal insulation properties. They help reduce noise transmission and act as a barrier against temperature transfer.

- Moisture Resistance: Certain types of sponge rolls offer resistance.

Adhesive Rolls and Tapes: Versatile Solutions for Various Applications

Adhesive rolls and tapes are ubiquitous in our daily lives, serving as essential tools for various applications. Whether it’s for packaging, crafting, or repairing, these versatile adhesive products offer convenient and reliable solutions. They are widely used in homes, offices, industries, and numerous other settings, making them an integral part of our modern world.

Adhesive rolls and tapes are designed to provide a strong bond between surfaces, allowing for the joining of materials, securing objects, or even mounting items onto different surfaces. They consist of a backing material coated with an adhesive substance that adheres to surfaces upon application of pressure. The backing material can be made of paper, plastic, cloth, or a combination of these materials, depending on the specific requirements of the application.

Another popular category of adhesive rolls and tapes is the double-sided tape. As the name suggests, this type of tape has adhesive on both sides, allowing it to bond two surfaces together. Double-sided tapes find numerous applications in the mounting of objects, such as hanging posters, attaching carpets, or even installing mirrors. They provide a clean and reliable alternative to traditional methods like nails, screws, or glue, as they often leave no marks or residue when removed.

In recent years, adhesive technology has seen significant advancements, leading to the development of innovative products with enhanced features. Some adhesive rolls and tapes now come with additional properties, such as high temperature resistance, UV resistance, or even repositionable adhesives that allow for easy repositioning during installation.

In conclusion, adhesive rolls and tapes are versatile tools that offer practical solutions for a wide range of applications. From packaging and mounting to painting and electrical insulation, these products have become an indispensable part of our daily lives. With ongoing advancements in adhesive technology, we can expect even more versatile and efficient adhesive rolls and tapes to emerge, catering to the evolving needs of various industries and individuals.