Silicone rubber extrusion refers to the process of shaping and forming silicone rubber into various profiles or shapes by forcing the material through a die. This manufacturing technique offers a range of benefits and is widely used in different industries for its unique properties.

Let’s explore the benefits and common uses of silicone rubber extrusion.

Benefits of Silicone Rubber Extrusion:

- Temperature Resistance: Silicone rubber exhibits excellent resistance to extreme temperatures, both high and low. It can withstand temperatures ranging from -60°C to 230°C (-76°F to 446°F) without losing its properties. This exceptional temperature resistance makes silicone rubber extrusions ideal for applications where exposure to heat or cold is a concern, such as automotive, aerospace, and industrial settings.

- Excellent Flexibility and Elasticity: Silicone rubber extrusions possess high flexibility and elasticity, allowing them to conform to different shapes and sizes. This flexibility makes them easy to install, bend, stretch, or compress as needed. It also enables silicone rubber extrusions to provide effective sealing and gasketing solutions for irregular or uneven surfaces.

- Superior Weather and UV Resistance: Silicone rubber exhibits excellent resistance to weathering, ozone, and UV radiation. It maintains its integrity and physical properties when exposed to outdoor conditions for extended periods. This weather and UV resistance make silicone rubber extrusions suitable for outdoor applications, including architectural sealing, electrical enclosures, and automotive weatherstripping.

- Excellent Electrical Insulation Properties: Silicone rubber is an excellent electrical insulator, offering high dielectric strength and low electrical conductivity. This makes silicone rubber extrusions ideal for applications that require electrical insulation, such as electrical enclosures, gaskets, and seals in electronics, appliances, and power distribution systems.

- Chemical Resistance: Silicone rubber has good resistance to many chemicals, including oils, solvents, acids, and bases. It maintains its properties when exposed to various chemical environments, making it suitable for applications in the chemical processing, pharmaceutical, and food industries.

Common Uses of Silicone Rubber Extrusion:

- Sealing and Gasketing: Silicone rubber extrusions are widely used for sealing and gasketing applications due to their excellent flexibility, temperature resistance, and sealing capabilities. They are employed in automotive weatherstripping, architectural sealing, HVAC systems, and industrial enclosures, providing effective sealing against moisture, dust, air, and noise.

- Electrical and Electronics: Silicone rubber extrusions find applications in the electrical and electronics industries due to their excellent electrical insulation properties. They are used as gaskets, seals, and insulation components in electrical enclosures, control panels, connectors, and wire harnesses, protecting against moisture, dust, and electrical interference.

- Medical and Healthcare: Silicone rubber extrusions are utilized in medical and healthcare applications due to their biocompatibility and sterilizability. They are used in medical devices, surgical instruments, and healthcare equipment, providing sealing, cushioning, and fluid transfer capabilities.

- Automotive and Transportation: Silicone rubber extrusions are commonly used in the automotive and transportation sectors due to their temperature resistance, weatherability, and sealing properties. They are employed in automotive weatherstripping, door seals, window seals, gaskets, and vibration dampening components.

- Industrial and Manufacturing: Silicone rubber extrusions find applications in various industrial and manufacturing processes. They are used for conveying materials, as conveyor belts or seals, in food processing, pharmaceutical manufacturing, and other industrial equipment.

In summary, silicone rubber extrusion offers several benefits, including temperature resistance, flexibility, weather and UV resistance, electrical insulation properties, and chemical resistance. These properties make silicone rubber extrusions versatile materials for sealing, gasketing, insulation, and protection in a wide range of industries such as automotive, electrical, medical, and industrial sectors.

Silicone rubber extrusion finds applications in various industries due to its unique properties and versatility. Here are some industries where silicone extrusions are commonly used:

- Automotive: Silicone extrusions are extensively used in the automotive industry for various applications. They are employed in automotive weatherstripping, door and window seals, gaskets, hoses, and vibration dampening components. Silicone extrusions provide excellent sealing capabilities, temperature resistance, and durability, making them ideal for automotive applications.

- Electrical and Electronics: The electrical and electronics industry utilizes silicone extrusions for their exceptional electrical insulation properties. They are used as gaskets, seals, and insulators in electrical enclosures, control panels, connectors, and wire harnesses. Silicone extrusions protect against moisture, dust, and electrical interference while providing reliable insulation.

- Construction and Architecture: Silicone extrusions are widely used in the construction and architectural sectors. They are employed for architectural sealing applications, such as window and door seals, expansion joint covers, and curtain wall gaskets. Silicone extrusions offer excellent weather resistance, UV stability, and flexibility, ensuring long-lasting and reliable sealing solutions.

- HVAC (Heating, Ventilation, and Air Conditioning): HVAC systems utilize silicone extrusions for various sealing and insulation applications. They are used as gaskets and seals in air handling units, ductwork, HVAC enclosures, and refrigeration systems. Silicone extrusions provide effective sealing against air leakage, temperature resistance, and excellent flexibility.

- Medical and Healthcare: The medical and healthcare industries rely on silicone extrusions for their biocompatibility and sterilizability. They are used in medical devices, surgical instruments, healthcare equipment, and laboratory applications. Silicone extrusions serve as sealing components, tubing, and fluid transfer solutions, meeting the stringent requirements of the medical field.

- Food and Beverage: Silicone extrusions are employed in the food and beverage industry due to their compliance with food-grade standards. They are used as gaskets, seals, and tubing in food processing and packaging equipment, ensuring safe and hygienic operations. Silicone extrusions offer resistance to high temperatures, chemicals, and maintain their integrity when in contact with food substances.

- Aerospace and Defence: The aerospace and defence sectors utilize silicone extrusions for various applications. They are employed in aircraft door seals, window seals, gaskets, vibration dampening components, and cable harnesses. Silicone extrusions provide excellent temperature resistance, weatherability, and durability required for demanding aerospace and defense environments.

- Industrial and Manufacturing: Silicone extrusions find applications in various industrial and manufacturing processes. They are used for conveying materials as conveyor belts or seals in food processing, pharmaceutical manufacturing, and other industrial equipment. Silicone extrusions provide resistance to temperature, chemicals, and mechanical wear, ensuring efficient and reliable operations.

- Energy and Power: Silicone extrusions are utilized in the energy and power industry for sealing and insulating applications. They are used in power generation equipment, transformers, switchgear, and electrical enclosures. Silicone extrusions provide effective sealing against environmental factors and offer electrical insulation properties for high-voltage applications.

- Marine and Offshore: The marine and offshore industries utilize silicone extrusions for sealing and protection against harsh marine environments. They are employed in boat and ship building, offshore platforms, and marine equipment. Silicone extrusions offer resistance to saltwater, UV radiation, and extreme temperatures, providing reliable sealing and longevity in marine applications.

These are just some of the industries where silicone extrusions are commonly used. The versatility, durability, temperature resistance, and sealing capabilities of silicone extrusions make them invaluable across a wide range of applications in numerous sectors.

Silicone rubber extrusion offers several benefits that make it a beneficial manufacturing process for various applications. Here are some key advantages of silicone rubber extrusion:

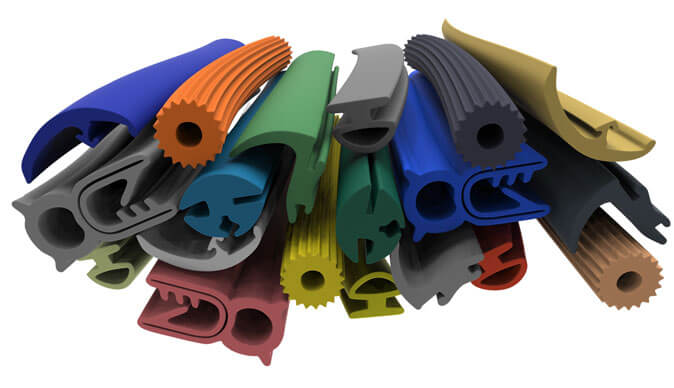

- Customizable Shapes and Profiles: Silicone rubber extrusion allows for the creation of customized shapes, profiles, and dimensions. The material is forced through a die, which can be designed to produce specific cross-sectional shapes or profiles according to the application requirements. This flexibility in design enables the production of complex shapes and precise dimensions, ensuring a tailored solution for each application.

- Excellent Temperature Resistance: Silicone rubber extrusions exhibit exceptional temperature resistance, making them suitable for applications that involve extreme temperatures. They can withstand both high and low temperatures without losing their physical properties or performance. Silicone rubber remains stable and maintains its flexibility and sealing capabilities across a wide temperature range, providing reliability and durability in demanding environments.

- Superior Flexibility and Elasticity: Silicone rubber is highly flexible and elastic, allowing it to adapt to various shapes, surfaces, and movements. This flexibility makes silicone rubber extrusions easy to install, bend, stretch, or compress, ensuring a proper fit and effective sealing in different applications. The material can recover its original shape after compression or deformation, providing long-lasting performance and sealing integrity.

- Exceptional Weather Resistance: Silicone rubber extrusions offer excellent resistance to weathering, UV radiation, ozone, and other environmental factors. They can withstand exposure to harsh outdoor conditions, including sunlight, extreme temperatures, and moisture, without degrading or deteriorating. This weather resistance ensures the longevity and performance of silicone extrusions, making them suitable for outdoor applications where sealing and protection are crucial.

- Chemical Resistance: Silicone rubber extrusions exhibit good resistance to a wide range of chemicals, including oils, solvents, acids, and bases. They maintain their properties and integrity when exposed to various chemical environments, ensuring long-term performance and reliability. This chemical resistance makes silicone extrusions suitable for applications in industries such as automotive, chemical processing, and manufacturing.

- Electrical Insulation Properties: Silicone rubber is an excellent electrical insulator, providing high dielectric strength and low electrical conductivity. Silicone rubber extrusions are commonly used in electrical and electronic applications where insulation and protection against electrical currents are required. They offer reliable insulation, ensuring safety, and preventing electrical interference or damage in sensitive electronic systems.

- Biocompatibility: Silicone rubber extrusions are biocompatible materials, meaning they are safe for use in medical and healthcare applications. They are compatible with human tissues and do not cause adverse reactions or harm when in contact with the body. This biocompatibility makes silicone extrusions suitable for medical devices, surgical instruments, and other healthcare applications.

- Easy to Clean and Maintain: Silicone rubber extrusions are easy to clean and maintain due to their non-stick properties and resistance to staining. The smooth surface of silicone rubber makes it less prone to the accumulation of dirt, debris, or contaminants. Additionally, silicone rubber can be easily cleaned using standard cleaning agents without the risk of damaging or degrading the material.

In summary, silicone rubber extrusion offers several benefits, including customizable shapes, excellent temperature resistance, superior flexibility and elasticity, exceptional weather resistance, chemical resistance, electrical insulation properties, biocompatibility, and ease of cleaning and maintenance. These advantages make silicone rubber extrusions a preferred choice for various applications across industries, providing reliable sealing, insulation, and protection in demanding environments.